The appropriate choice of machinery for the plastics industry is a critical factor that defines the competitiveness and quality of production.

And the precise selection of equipment for plastic transformation is an operational necessity, especially today, since it impacts the efficiency of the processes, the optimization of resources and the ability to adapt to market demands, in addition. that it is key to stand out and prosper in this industry.

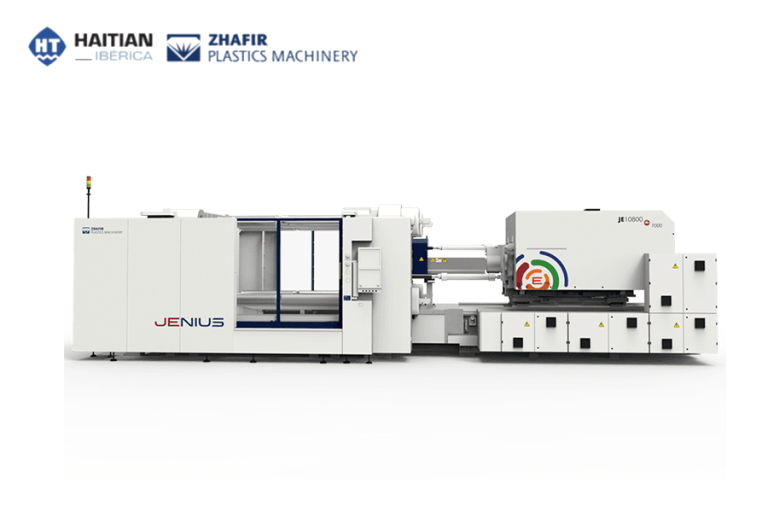

At HAITIAN, we understand the importance of being at the forefront of plastic injection technologies, and that is why we present this complete guide that goes beyond the choice between hydraulic, hybrid or electric machinery.

Equipment for Plastic Transformation: A Comprehensive Vision

The machinery for the plastics industry is not only a series of tools; rather, it stands as the essential backbone in every transformation operation.

From the extruders, responsible for shaping the polymers, to the advanced injection molding machines that make the final products, these equipment are the fundamental protagonists that outline the intrinsic efficiency and versatility of your production process.

Hydraulic Injection: Power and Reliability

Hydraulic injection machinery has maintained its position as a reliable option in the plastics industry over decades. Its strength lies in the ability to handle considerable volumes of molten plastic and its power in the injection process. Below, we’ll further explore the technical details that make this option a robust choice for high-demand applications:

1. Capacity for Large Volumes:

• Hydraulic injection is distinguished by its exceptional capacity to manage considerable volumes of molten plastic, consolidating itself as the preferred choice in industrial processes that demand mass-scale production.

• Inherent hydraulic power allows for rapid mold filling, ensuring efficient product replication with each injection cycle.

2. Power and Speed in Injection:

• The inherent strength of hydraulic systems facilitates high-pressure plastic injection, ensuring precise forming of intricately detailed parts.

• The response speed of these systems contributes significantly to the efficiency of production cycles, optimizing times and maximizing machinery productivity.

3. Key Technical Considerations:

• Careful selection of hydraulic equipment demands special attention to fluid management and control systems, ensuring optimal and reliable operation.

• Focusing on the maintenance considerations and technological innovations that have kept hydraulic injection a trusted option is essential to understanding its durability and power over time.

Hybrid Solutions: Energy Efficiency and Performance

Hybrid injection equipment represents an innovative synthesis, combining hydraulic power with the energy efficiency inherent to electrical systems. In this section, we will explore how this amalgam provides optimized performance, reducing energy consumption and highlighting its position as industry leaders.

1.Combination of Power and Energy Efficiency:

• Hybrid injection equipment represents an innovative synthesis by integrating hydraulic power with the energy efficiency of electrical systems.

• This balanced combination takes advantage of hydraulic power for the initial injection, while using electrical energy for pressure maintenance and other phases of lower demand, thus significantly reducing energy consumption.

2.Optimal Performance in Specific Applications:

• These systems demonstrate their effectiveness outstandingly in applications that require high precision and shorter production cycles.

• The specific advantages they offer over purely hydraulic or electric options are evident in terms of performance and versatility.

3.Technological Innovations:

• From energy recovery systems to advances in automatic controls, they boost the efficiency and performance of injection machinery.

Electrical Injection: Precision and Sustainability

Electric injection machines represent the cutting edge in precision and sustainability in the plastics industry. This section will analyze in depth how electric technology not only increases the quality of the final product, but also contributes significantly to the reduction of environmental impact, with practical examples and key advantages.

1. Millimeter Precision:

• Electric injection machines represent the cutting edge in terms of precision, being capable of providing millimetric results in the formation of plastic parts.

• Electrical technology directly influences the consistency and uniformity of injected products, especially in applications that require tight tolerances.

2. Focus on Sustainability:

• Electric machines contribute to sustainability by significantly reducing energy consumption and minimizing waste generation compared to hydraulic systems.

• The choice of this equipment has led to tangible improvements in energy efficiency and reduction of the ecological footprint.

3. Key Advantages in Production:

• The additional benefits of opting for electric machinery, such as faster cycle times, lower long-term operating costs and greater ease of maintenance, are enormous.

• Specific technological innovations have consolidated electrical injection as the preferred option in various industrial applications, boosting the quality and efficiency of the injection process.

HAITIAN: Your Partner in Machinery for the Plastics Industry

As a plastic injection machinery service and distribution company, HAITIAN is your comprehensive partner, committed to providing services and distributing machinery of the highest quality:

1. Commitment to Excellence:

• HAITIAN is distinguished by its firm commitment to excellence in all aspects of its operations. From machinery selection to service delivery, we strive to exceed expectations, ensuring our customers have access to top-notch equipment backed by unwavering quality standards.

• Our dedication is reflected in the meticulous choice of business partners, in the continuous training of our staff and in the implementation of practices that optimize customer satisfaction.

2. Leadership in Services and Distribution:

• We aspire to be leaders in the service and distribution of plastic injection machinery in Spain. This ambition translates into an unwavering commitment to efficiency, punctuality in deliveries and personalized attention to each client.

• We strive to set a standard in the Spanish market, not only supplying cutting-edge equipment, but also providing after-sales services that guarantee optimal performance over time.

3. Innovation as a Fundamental Pillar:

• We embrace innovation as a fundamental pillar in our business philosophy. We are constantly exploring new technologies and trends in the plastic injection industry to offer our clients advanced solutions that boost their competitiveness.

• Innovation is not limited to machinery; It is also reflected in our internal processes, in the continuous adaptation to changing market needs and in the proactive anticipation of future industry demands.

4. Strategic Ally in the Transformation of Plastic:

• We collaborate closely with our clients, understanding their specific needs and providing personalized solutions that optimize their production processes.

• We are proud to be an integral part of our clients’ success, offering technical advice, specialized training and a long-standing commitment to their prosperity in the industry.

Thus, our dedication to excellence, leadership in services, innovative approach and role as a strategic ally distinguish us in the business landscape, offering the plastic transformation industry more efficiency, quality and sustainable growth.

Contact us if you need more information.