Plastic injection molding is a fundamental process in the manufacturing of a wide variety of products, from automotive components to packaging and electronic devices. This technique has become a cornerstone of the plastic transformation industry due to its ability to produce complex and high-quality parts efficiently and precisely.

The success of the injection molding machine process heavily depends on selecting the right plastic injection molding machine. With various technologies available, such as hydraulic, electric, and hybrid injection molding machines, it is crucial to understand the differences and advantages of each type to make an informed decision.

Importance of Choosing the Right Machine

Choosing the correct plastic injection molding machine is essential for optimizing production, improving product quality, and reducing operating costs. Each type of machine has its characteristics, advantages, and specific applications, which can significantly influence the performance and efficiency of the molding process.

Factors such as the type of plastic material, the size and complexity of the parts, production requirements, and budget constraints must be considered when choosing the right machine. An informed decision can lead to higher productivity, lower energy consumption, and better quality of the final product.

What is Injection Molding?

Injection molding is a manufacturing process used to produce plastic parts by injecting molten material into a mold. This method allows the production of parts with complex shapes and precise details efficiently and repetitively.

The process begins with melting the plastic material, which is then injected at high pressure into a closed mold. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. This cycle is repeated to produce large volumes of identical parts.

Main Components of an Injection Molding Machine

A plastic injection molding machine consists of several key components, including:

- Hopper: Container where the plastic material in pellet form is fed.

- Injection Unit: Responsible for melting and injecting the plastic material into the mold.

- Mold: Tool that shapes the molten plastic to create the final part.

- Clamping Unit: Holds the mold closed during the injection and solidification of the plastic.

- Control System: Allows the programming and monitoring of process parameters.

Basic Injection Molding Process

The injection molding process can be divided into several stages:

- Mold Clamping: The clamping unit ensures that the mold is firmly closed to receive the plastic material.

- Injection: The molten plastic material is injected into the mold at high pressure.

- Cooling: The plastic inside the mold cools and solidifies.

- Mold Opening: The clamping unit opens to release the molded part.

- Ejection: The finished part is ejected from the mold, and the cycle repeats.

Hydraulic Injection Molding Machines for the Plastic Transformation Industry

Hydraulic injection molding machines are the most traditional in the plastic transformation industry. They use hydraulic systems to generate the necessary force for the injection and mold clamping processes.

The operation of a hydraulic machine involves using hydraulic pumps that drive fluid to the cylinders, creating the pressure needed to move the mechanical components. This pressure allows the injection of the molten plastic into the mold and the clamping of the mold during the solidification process.

Key Components and Features

- Hydraulic Unit: Includes pumps, valves, and hydraulic cylinders that generate the injection and clamping force.

- Control System: Manages process parameters and adjusts hydraulic pressure as needed.

- Hopper and Injection Unit: Melt and transport the plastic material to the mold.

- Clamping Unit: Uses hydraulic cylinders to keep the mold closed during injection.

Advantages of Hydraulic Machines

- Versatility: Suitable for a wide range of applications and plastic materials.

- Clamping Force: Capable of generating high clamping forces required for large and complex molds.

- Initial Cost: Generally, they have a lower initial cost compared to electric machines.

Typical Applications

Hydraulic machines are ideal for producing large and complex parts that require high clamping force. They are commonly used in the automotive industry, household appliances, and the manufacturing of containers and large-sized products.

Electric Injection Molding Machines for the Plastic Transformation Industry

Electric injection molding machines use electric servo motors instead of hydraulic systems to generate the necessary force for the injection and mold clamping processes. These servo motors allow for more precise and efficient control of the machine’s movements.

The operation of an electric machine involves converting electrical energy into mechanical motion through servo motors, which drive the injection screws and clamping plates. This system eliminates the need for hydraulic fluids and significantly reduces energy consumption.

Key Components and Features

- Electric Servo Motors: Provide the injection and clamping force with high precision.

- Control System: Manages the movements of the servo motors and adjusts process parameters.

- Hopper and Injection Unit: Melt and transport the plastic material to the mold.

- Clamping Unit: Uses servo motors to keep the mold closed during injection.

Advantages of Electric Machines

- Energy Efficiency: Consume less energy than hydraulic machines, reducing operating costs.

- Precision: Offer more precise control of movements, improving product quality.

- Lower Maintenance: Without hydraulic fluids, they require less maintenance and have a longer lifespan.

- Cleaner Operation: Eliminate the risk of hydraulic oil leaks, resulting in a cleaner working environment.

Typical Applications

Electric machines are ideal for producing small to medium-sized parts that require high precision and repeatability. They are widely used in the electronics, medical, and consumer products industries, where quality and energy efficiency are priorities.

Hybrid Injection Molding Machines for the Plastic Transformation Industry

Hybrid injection molding machines combine elements of both hydraulic and electric technologies to leverage the advantages of each. They use electric servo motors for precise movements and hydraulic systems to generate the necessary clamping force.

The operation of a hybrid machine involves integrating servo motors for injection control and hydraulic systems for mold clamping. This combination allows a balance between energy efficiency, precision, and clamping force.

Key Components and Features

- Electric Servo Motors: Control injection movements with high precision.

- Hydraulic Systems: Generate the clamping force needed for large and complex molds.

- Control System: Coordinates the electric and hydraulic components to optimize the process.

- Hopper and Injection Unit: Melt and transport the plastic material to the mold.

- Clamping Unit: Uses a combination of servo motors and hydraulic systems to keep the mold closed.

Advantages of Hybrid Machines

- Energy Efficiency: Better than traditional hydraulic machines but less than pure electric machines.

- Precision and Control: Offer a good balance between precision and clamping force.

- Versatility: Suitable for a wide range of applications and plastic materials.

- Lower Maintenance: Require less maintenance compared to hydraulic machines.

Typical Applications

Hybrid machines are suitable for a variety of applications requiring both precision and high clamping force. They are used in the automotive industry, consumer products, and the manufacturing of technical parts where a balance between performance and efficiency is needed.

Factors to Consider When Choosing an Injection Molding Machine

When selecting a plastic injection molding machine, it is important to consider several key factors:

- Type of Plastic Material: Different materials have different processing requirements.

- Size and Complexity of Parts: The dimensions and complexity of the molded parts will determine the required clamping force and precision.

- Production Requirements: The production volume will influence the choice between electric, hydraulic, or hybrid machines, as some are more suitable for mass production while others are better for smaller runs.

- Budget: Initial cost and operating costs are crucial factors. Electric machines tend to have higher initial costs but offer lower operating costs due to their energy efficiency.

- Maintenance: Consider the ease and cost of maintenance. Electric machines usually require less maintenance than hydraulic ones.

- Available Space: The machine’s dimensions must fit the available space in the production facility.

Evaluating these factors will help in selecting the machine that best fits the specific production needs and optimizes available resources.

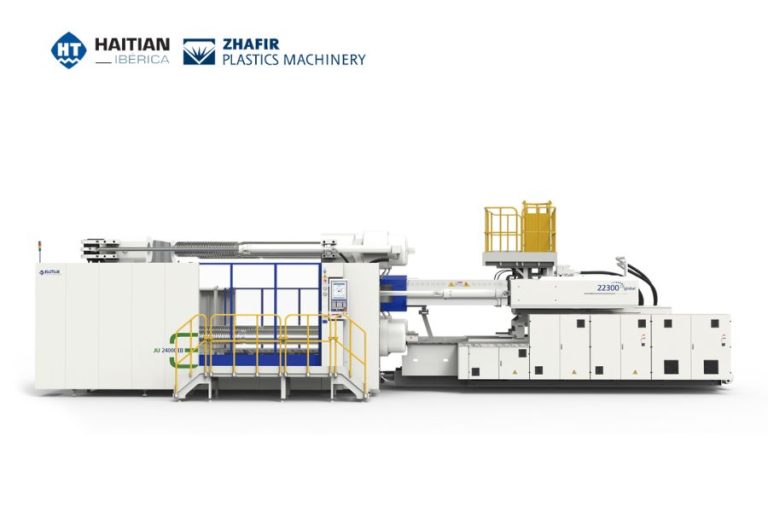

Haitian Ibérica: We Import and Sell Machinery for the Plastic Transformation Industry

At Haitian Ibérica, we are leaders in importing and selling high-quality plastic injection molding machines. Our extensive range of products includes hydraulic, electric, and hybrid solutions to meet the diverse needs of the plastic transformation industry. We are committed to providing cutting-edge technologies that enhance the efficiency and precision of your production processes.

Our team of experts is available to assist you in choosing the most suitable machine for your business, ensuring that you achieve maximum performance and quality in your operations. Additionally, we offer technical support and maintenance to ensure your equipment operates optimally at all times.

If you are looking to optimize your plastic production, contact us today to discover how our plastic injection molding machines can transform your business and why so many industry professionals trust Haitian Ibérica.