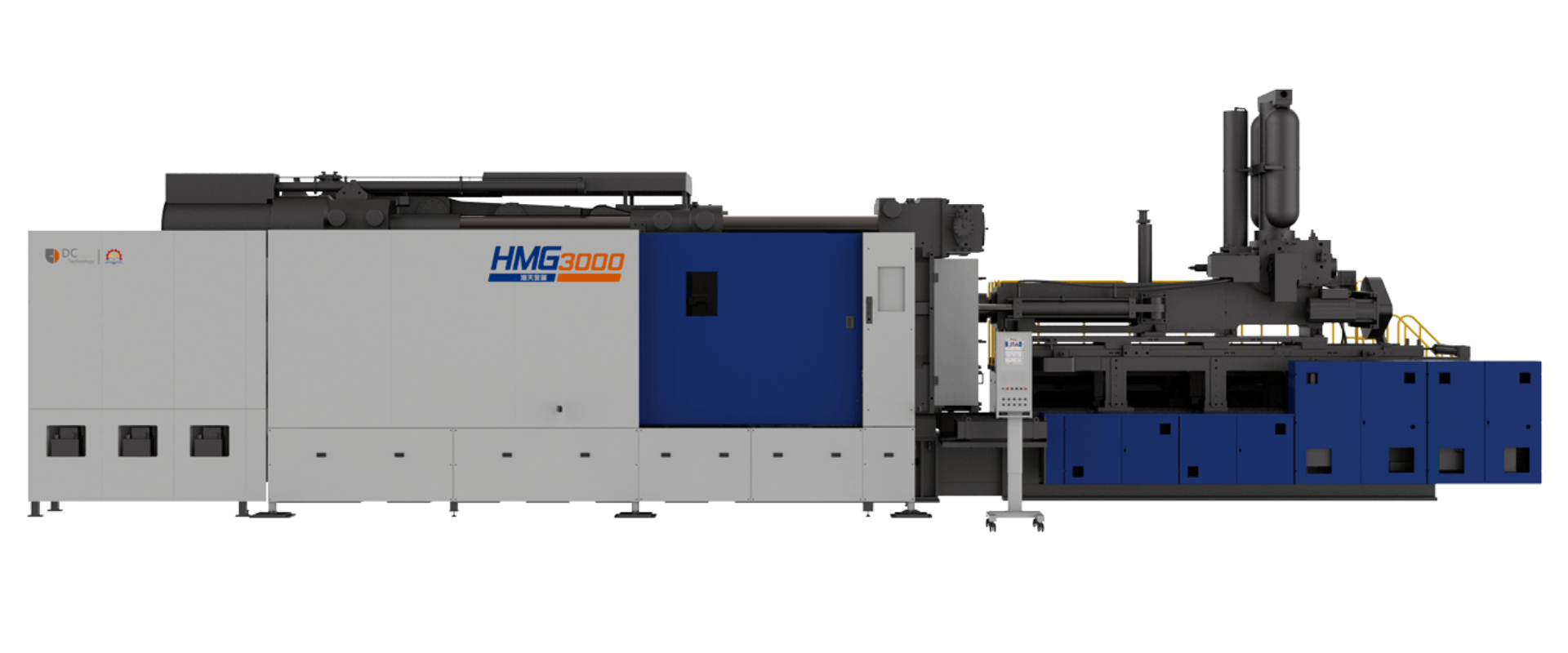

Serie HMG

Thixomolding magnesium Injection Machines

HMG350T - HMG3000T Serie

Injection systems with superior performance

- Full real-time control injection system.

- Injection speed of 0.05-5m/s

- Metering ejection and metering rotation controlled by servo motor

- Enlarged accumulator and nitrogen cylinder

- Injection electric heating circuit

High rigid clamping structure

- Three thickened plates

- Reinforced structure of the mid-plate

- Special thickened large bar and lock shaft

- Bronce adjustment nut with aluminium

Clamping Unit

- The mold can be efficiently stopped at any position.

- The mid-plate is configured with a P20 mold-steel auxiliary formwork (700 and above models)

Injection unit

- Full real-time control injection system with a pressure of 19MPa

- For screws with a diameter of Ø130mm and above, it is equipped with a double-section barrel with low maintenance

Control Unit

- The intelligent and powerful KEBA control system, for quick view of injection and storage curves, and it can be configured to interact with the intelligent factory management software

Drive Unit

- Energy-saving and reliable high-performance servo system

- Multiple hydraulic oil filtration

- EtherCAT digital data interaction

Injection Speed

0,05-5 m/s

Control System

Smart Injection in real time

Screw Diameter

Up to 150mm

Clamping Unit

Three thickened plates and reinforced structure of the mid-plate

Energy Saving

High performance and efficiency servo system

Injection Volume (magnesium)

Up to 10 kg

Thixomolding magnesium injection machines

HMG Serie

- Currently largest Thixomolding machine worldwide

- Application results with better density and higher mechanical properties

- Clamping forces up to 30,000 kN

- Screw diameters up to 150 mm

- Theoretical injection volume up to 10 kg

Features

Injection systems with superior performance

Injection systems

- Full real-time control injection system

- Injection speed of 0.05-5m/s

- Metering ejection and metering rotation controlled by servo motor

- Enlarged accumulator and nitrogen cylinder

- Injection electric heating circuit

Injection unit

- Full real-time control with 19MPa pressure

Structure and clamping unit

Clamping structure

- Three thickened plates

- Reinforced structure of the mid-plate

- Special thickened large bar

- Lock shaft

- Bronce adjustment nut with aluminium

Clamping unit

- The mold can be efficiently stopped at any position

For more information contact us

Our team of specialists is ready to answer all your questions and provide you with the advice you need.

Please fill out the form and we will contact you to offer you the option that best suits your needs.

Applications

Automotive

Appliances

Containers

Logistics

Plastic injection molding machines: what they are, how they work, and how to choose the ideal machine

Plastic injection molding machines are essential equipment for transforming polymers into finished products. Their role.

Alejandra Todoli

17 September, 2025What Are Hilectro XTC Robots in Plastic Injection Process Automation?

In today’s industrial manufacturing environment, where efficiency, precision, and competitiveness are key, Hilectro XTC

Alejandra Todoli

20 August, 2025Haitian Mars V H: Technical Advantages of the High-Capacity Injection Molding Machine

The Haitian Mars V H is a servo-hydraulic injection molding machine from Haitian’s fifth-generation Mars...

Alejandra Todoli

16 July, 2025