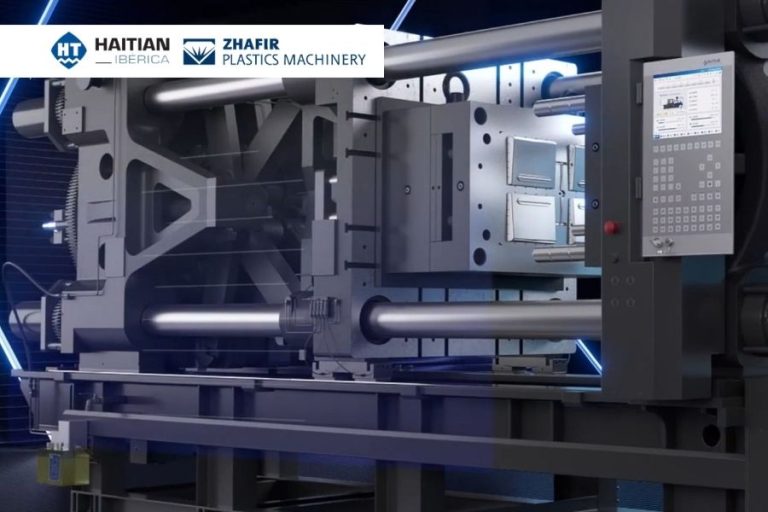

The world of plastic manufacturing demands equipment that guarantees precise, efficient results and adaptability to market demands. In this context, the Haitian Mars V injection molding machine stands as a cutting-edge, comprehensive solution for the production of high-quality components. In this article, we will delve into the features and advantages of this injection molding equipment, from its fifth-generation technology to its technical specifications and its ability to adapt to future industrial challenges.

The evolution of injection molding

Injection molding has become an essential process in modern manufacturing. It allows for the mass production of complex parts with strict tolerances, being crucial in sectors such as automotive, medical, electronics, and consumer goods. In this environment, having a plastic injection machine that offers precision, speed, and energy efficiency is fundamental.

Haitian has led innovation in this field for decades, developing equipment that combines advanced technology and intelligent solutions. The Mars V, part of the MA5 series, sets the new standard in injection molding. This equipment not only saves energy through its fifth-generation technology, but it also integrates improvements in plastification and mold clamping structures, optimizing the overall process performance.

Fifth-generation innovation and technology

The MA5 series, which includes the Haitian Mars V, represents a significant leap in injection machine design. Among the standout features are:

- Energy savings: The implementation of servo-hydraulic systems allows power to be adjusted according to the specific needs of each injection cycle, reducing electricity consumption and, therefore, operating costs.

- Process optimization: Each component of the system, from plastification to clamping structure, has been reviewed and improved to increase efficiency and process stability.

- Adaptable design: The hardware configuration continues to evolve, offering aesthetic and functional improvements that not only meet current standards but are also designed to adapt to future innovations in the industry.

These features position the Haitian Mars V as a plastic injection machine capable of meeting the most demanding challenges, ensuring consistent, high-precision results in every cycle.

Technical specifications and performance

For those seeking injection molding equipment that delivers exceptional performance, the Haitian Mars V stands out with its impressive technical specifications:

- Clamping unit: With a capacity ranging from 600 to 33,000 kN, the Mars V can accommodate molds of various sizes and force requirements, making it ideal for a wide range of industrial applications.

- Injection volume: The equipment allows for volumes ranging from 49 to 45,616 cm³, offering flexibility in the production of both small and large parts.

- Platen size: With dimensions ranging from 470×470 mm to 3100×3020 mm, the Mars V adapts to different mold configurations, maximizing productivity without compromising workspace.

- Distance between columns: The range of 310×310 mm to 2160×1900 mm allows for various mold structures, ensuring uniform pressure distribution.

- KEBA control panel: This advanced control system facilitates process programming and monitoring, allowing for precise real-time adjustments.

- Screw diameter: With a range from 24 to 220 mm, the injection screw adapts to different types of material and volumes, ensuring optimal plastification.

Additionally, the injection group integrates IU structures, double-layer linear guides, an energy-saving heating device, and a closed-loop injection control. All of this is complemented by a high-rigidity platen structure that evenly distributes pressure across the entire surface, ensuring stable clamping and preventing deformation.

Integrated smart technologies

One of the great advantages of the Haitian Mars V is the integration of multiple smart technologies. These systems not only allow for customizable and flexible production, but they also increase productivity and the quality of the final product. Among the integrated technologies are:

- Closed-loop injection control: Ensures the process remains within optimal parameters, reducing variations and waste.

- Real-time monitoring systems: Thanks to the KEBA control panel, it is possible to monitor every phase of the process, facilitating decision-making and continuous optimization.

- Double-layer linear guides: Ensure smooth and precise movement of the screw and injection, resulting in greater accuracy in manufacturing each part.

- Energy-saving heating device: This component significantly contributes to reducing electrical consumption, making the Mars V a sustainable and cost-effective option.

These innovations ensure that the Haitian Mars V not only meets current standards but is also easily adaptable to future market demands, offering a truly intelligent production solution.

Integration and flexibility in production

The ability to integrate the Haitian Mars V into automated production lines is another of its great strengths. This equipment seamlessly connects with automation and robotics systems, making the transition to smart factories easier. Thanks to its modular design and real-time monitoring technology, operators can dynamically adjust production parameters, allowing them to quickly adapt to changes in demand or product specifications.

Advantages of integration:

- Ease of connection to automated systems.

- Intuitive interface for real-time adjustments.

- Adaptability to different plant configurations.

- Specialized technical support for complete integration.

This flexibility not only improves operational efficiency but also reduces downtime and the costs associated with launching new production lines.

Applications in various industries

The versatility of the Haitian Mars V allows it to be used in a wide range of sectors, where precision and efficiency are essential:

Automotive Industry

- Structural and decorative components: The Mars V is ideal for producing complex parts that demand high precision and consistency, such as dashboards, bumpers, and safety elements.

Medical Industry

- High-precision devices and components: In the medical sector, where every millimeter counts, this machine ensures the production of devices that meet rigorous quality and sterility standards.

Electronics Industry

- Casings and technical components: The production of electronic components requires precision in dimensions and tolerances, something the Mars V achieves with great consistency.

Consumer Goods

- Everyday products: From home appliances to kitchen utensils, the machine allows for mass production of high-quality finished products.

Each of these sectors benefits from the Haitian Mars V’s ability to adapt to different production volumes and material types, ensuring precise and efficient results.

The smart choice for high-precision production

The Haitian Mars V stands as the ideal plastic injection machine for companies seeking precision, efficiency, and adaptability in their production lines. With fifth-generation energy-saving technology, an innovative design, and high-performance technical specifications, this equipment sets the standard in injection molding equipment for industries demanding the best.

Every detail, from its clamping unit to the advanced KEBA control panel, has been designed to deliver consistent, high-quality results, allowing manufacturers to reduce costs, minimize waste, and adapt to the challenges of an ever-evolving market.

Investing in the Haitian Mars V is investing in a solution that not only meets current needs but is also prepared for the future of manufacturing. Its ability to integrate into automated systems and its compatibility with various industrial applications make this equipment an essential tool for companies committed to excellence and innovation.