In the world of plastic product manufacturing, efficiency and productivity are vitally important factors.

This industry is constantly evolving and competing, requiring companies to be more efficient than ever to remain competitive in the global market.

Efficiency translates into optimal use of resources, less material waste and faster production, which in turn is directly related to productivity.

Productivity in the manufacturing of plastic products is measured not only in terms of the quantity of finished products, but also in the quality and consistency of those products. Customers and end consumers increasingly demand products that meet high quality standards and are produced efficiently. This implies the need for advanced production technologies and processes that can ensure fast and accurate production.

In this context, the choice of the appropriate machinery plays a fundamental role. Electric injection equipment, such as those offered by Haitian, are transforming the way plastic is produced by offering a number of key advantages, such as energy efficiency, precision and reduced maintenance costs.

What Are Electrical Injection Equipment?

Electrical injection equipment is an innovative category of machinery used in the plastic processing industry. Unlike conventional injection machines, which typically rely on hydraulic systems to operate, electric injection machines use high-precision electric motors to carry out the plastic injection process.

They are characterized by their energy efficiency, precision and ability to deliver consistent results. Its operation is based on the principle of converting electrical energy into mechanical movement. When the injection process begins, an electric motor drives the injection screw to melt and compress the plastic material, which is then injected into the mold to create the final part. The ability to precisely control speed, pressure and temperature during this process is one of the main advantages of electric injection equipment.

Electric injection machines are used in a wide variety of applications, from the manufacturing of high-precision plastic parts for the automotive and medical industries to the production of everyday plastic containers and utensils. Its versatility and ability to adapt to different production needs make electric injection equipment an attractive option for companies seeking to improve their efficiency and quality in the manufacturing of plastic products.

Advantages of Electrical Injection Equipment

These are equipment that have gained popularity in the plastic processing industry due to their numerous advantages:

- Energy Efficiency

They are highly efficient in terms of energy consumption. Unlike hydraulic injection machines, which constantly consume energy, electric machines only use energy when necessary. This translates into significant savings over time.

- Precision and Control

They offer precise control over speed, pressure and temperature during the injection process. This ensures consistency and quality of the final product, which is essential in applications where precision is key.

- Less Maintenance

Unlike hydraulic machines, they have fewer moving parts and components subject to wear. This reduces the need for maintenance, resulting in less downtime and reduced operating costs.

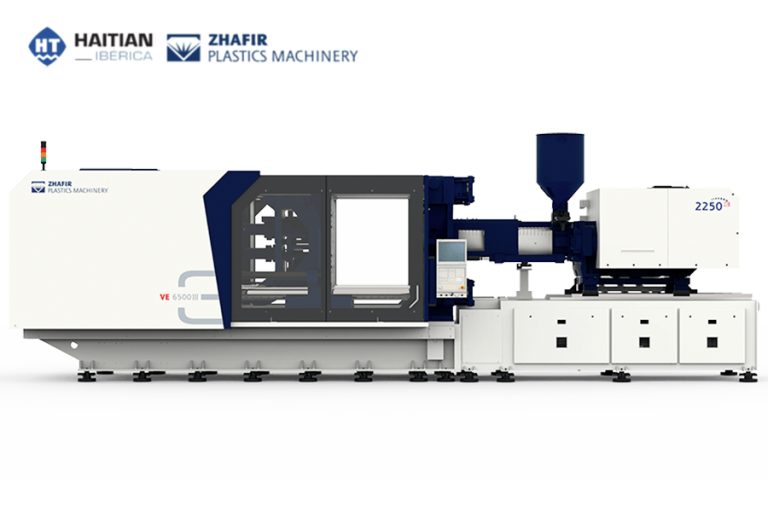

Haitian Electrical Injection Machines

Haitian, a leading company in the plastic processing machinery industry, has been at the forefront of innovation in electrical injection equipment. Below are some of the features of their equipment:

- Cutting-edge technology

It incorporates state-of-the-art technology in its electric injection machines, which guarantees optimal performance and a longer useful life. Its advanced control systems allow for customized programming and real-time monitoring, making it easy to optimize processes.

- Wide Range of Sizes

Offers a wide range of electric injection machine sizes to suit various production needs. Whether you are producing small precision parts or large products, Haitian has a solution for you.

- Commitment to Sustainability

It cares about the environment and designs its machines to be respectful of it. The energy efficiency of your equipment helps reduce the carbon footprint of your operation and comply with the strictest environmental standards.

- Global Technical Support

It not only offers high-quality equipment, but also backs its customers with strong customer service and technical support around the world. This ensures that your investment in electric injection equipment is backed by experts in the industry.

With its focus on energy efficiency, precision and sustainability, our company offers cutting-edge solutions for companies looking to improve their productivity and reduce operating costs.

Differences between Electrical and Hydraulic Injection Equipment: Why Choose Haitian Electrical Injection Equipment?

When it comes to the manufacturing of plastic products, it is essential to understand the key differences between electrical injection equipment and hydraulic injection equipment, both available in Haitian, to make informed and profitable decisions. Next, we will mention the main differences between these two technologies:

- Energy Efficiency

- Precision and Control

- Less Maintenance

- Adaptability and Versatility

Frequently asked questions

-In which industries are electrical haitian equipment commonly used?

Electrical injection equipment is versatile and used in a wide variety of industries, including automotive, medical, packaging, electronics and many others where precision and quality are critical.

-What are the advantages of precision in electrical injection equipment compared to other systems?

Electric injection equipment offers exceptional precision in terms of speed, pressure and temperature control during the injection process. This enables the production of high-quality, consistent plastic parts, which is crucial in applications requiring tight tolerances.

-Why is electrical injection equipment considered to be more efficient in energy terms?

Electric injection equipment is more efficient because it only consumes energy when it is required for the injection process. On the other hand, hydraulic injection equipment tends to maintain a constant charge of oil under pressure, which results in greater energy consumption.

Ready to Transform Your Production with Electrical Injection Equipment from Haitian?

If you are interested in optimizing your plastic product manufacturing process and taking advantage of the advantages of electric injection equipment, contact us today!

Our team of machinery experts will be happy to provide you with additional information, answer your questions, and help you find the perfect solution for your specific needs.