In the plastics transformation industry, having quality, high-performance hydraulic injection machines is essential to guarantee efficient processes and excellent products.

At HAITIAN, a company specialized in the import and sale of machinery for the plastic transformation industry, we offer innovative solutions that combine power and precision. In this article, we will introduce you to our hydraulic injection equipment, highlighting its features and benefits. Find out how our solutions can drive the success of your business in the field of polymer injection.

Hydraulic injection: versatile and efficient technology

Hydraulic injection is a process used in the plastic transformation industry to manufacture parts and products by injecting molten plastic material into molds.

This technology is based on the use of hydraulic systems to generate the necessary pressure and control the flow of the material.

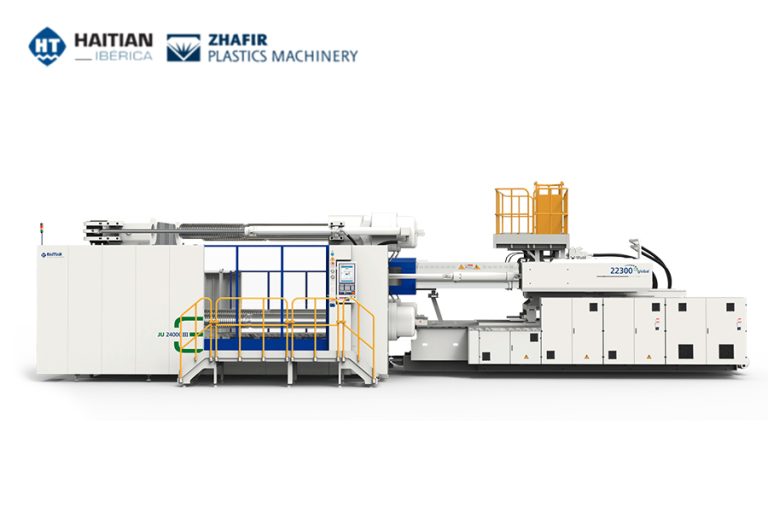

In this sense, our company provides a wide range of hydraulic injection machines with enormous power and precision in each process.

Our machinery is designed with state-of-the-art technology and advanced control systems, allowing greater efficiency in production and high quality in the manufactured parts.

They stand out for their robustness, durability and ability to adapt to various applications. We have models with different injection capacities and closing forces, which allows us to satisfy the needs of different industrial sectors.

Characteristics of our hydraulic injection machines and equipment

At HAITIAN, we are proud to offer equipment with outstanding features, since they have state-of-the-art control systems that allow precise adjustment of injection, temperature, and pressure parameters, guaranteeing reproducibility and consistency in production.

In addition, they have advanced security systems to protect both the operator and the equipment. These systems include locking devices, safety sensors and guards to prevent accidents and ensure a safe working environment.

Energy efficiency is also a priority in our hydraulic injection machines. We use technologies and components that optimize energy consumption, thus reducing operating costs and minimizing environmental impact.

Thanks to the combination of power, precision and versatility, our hydraulic injection machines and equipment are the perfect choice for companies looking to increase their production capacity and obtain high-quality products in the plastics transformation industry.

In short, they offer:

- Exceptional Performance: The Key to Our Hydraulic Injection Machines At HAITIAN, we are proud to offer hydraulic injection machines with exceptional performance. Our machines are designed with the latest technology and quality components to ensure efficient operation and consistent results. From clamping power to precise injection control, our machines deliver optimal performance at every stage of the injection molding process. With our range of models and capacities, we can satisfy various production needs in the plastics industry.

- Precision and control: Outstanding characteristics of our hydraulic injection machines Precision is fundamental in the plastic injection process, and our machines are designed to offer precise control in every detail. With advanced control and monitoring systems, our machines allow you to adjust key parameters such as pressure, injection speed and cooling time, ensuring a faithful reproduction of designs and high quality in the parts produced. Plus, the intuitive interface makes it easy to set up and monitor the process, allowing you to maximize efficiency and reduce cycle times.

- Versatility and adaptability: Complementary equipment for your success in plastic injection At HAITIAN, we understand that each plastic injection project is unique and requires adapted solutions. That’s why we offer a wide range of complementary equipment that allows you to expand the capabilities and improve the efficiency of your operations. From precise dosing and mixing systems to parts handling and extraction units, our equipment is designed to integrate seamlessly with our hydraulic injection machines, providing you with a complete and versatile solution for your production needs.

Differences between hydraulic injection and other manufacturing methods

Hydraulic injection differs from other manufacturing methods in several key aspects. Here are some notable differences:

- Power: it is characterized by its ability to generate high injection pressure, which allows fast and efficient filling of the molds. In addition, hydraulic technology offers precise control of material flow, resulting in products with fine details and a high quality finish.

- Production costs: it can offer a favorable cost-benefit ratio. This technique allows high productivity, minimizing cycle time and maximizing process efficiency. Additionally, the ability to reproduce the exact same part over multiple production runs contributes to cost reduction in the long run.

- Design flexibility: allows the creation of products with complex designs and varied geometries. The molds used in this process can be customized to fit the specific needs of the product, providing extensive design freedom and creative possibilities.

- Automation – Benefits from advances in control technology, allowing for greater automation and monitoring of the process. Modern control systems offer precise programming and adjustment options, ensuring consistent and reliable production.

Frequently Asked Questions

-What kind of products can be manufactured with hydraulic injection?

Hydraulic injection is suitable for a wide range of plastic products, from small parts to large components. It is used in various industries such as automotive, electronics, packaging, toys, and more. The versatility of this technique allows the manufacture of products with complex designs and fine details.

-What are the important aspects to consider when selecting hydraulic injection equipment?

Factors such as injection capacity, clamping force, mold plate size, process speed and accuracy, compatibility with different materials, and manufacturer’s reputation are important to consider. In addition, it is crucial to evaluate the specific production needs and the requirements of the final product to make the right decision.

-What safety measures are implemented in hydraulic injection machines?

They are equipment designed with multiple safety measures to guarantee the protection of operators and prevent accidents. These measures include locking and access control systems, security sensors, light curtains, protections in dangerous areas and emergency stop devices. In addition, safety training is provided to operators so that they can work safely with the machinery.

Support and quality service

At HAITIAN, our commitment does not end with the sale of our machines and equipment. We pride ourselves on providing excellent after-sales support and service to ensure your continued success. Our team of professionals works closely with you, providing technical advice, training and assistance in the installation and commissioning of our hydraulic injection machines. In addition, we offer maintenance and repair services, ensuring that your equipment works optimally and minimizing downtime.

Discover our solutions and take advantage of the potential of plastic injection in your business. Contact us today and give your production a boost!