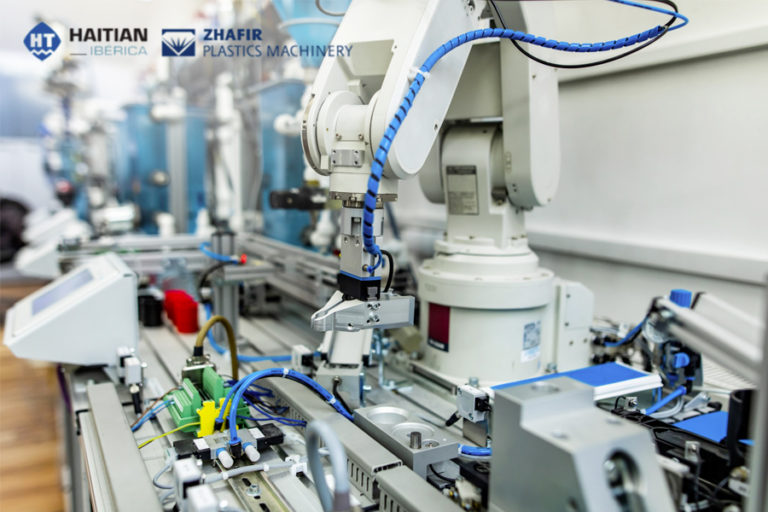

MAGBO offers great solutions within the plastic injection industry. They are a benchmark in the sector, whose machinery enjoys the best technology, with the aim of providing customers with the most efficient and cutting-edge options.

Their machinery for plastic injection means providing companies with more business opportunities, greater profitability and productivity. They are ideal equipment for quick mold and die change, metal stamping, die casting and rubber molding.

The maintenance of the machines for the plastic injection industry MAGBO is very fast and flexible, in addition to the repairs of possible incidents are easier to solve, since the components and finishes are made of excellent materials.

Features of MAGBO industrial equipment

MAGBO equipment undoubtedly brings great innovations in the field. Their characteristics endorse them.

When exploring the casino scene in New Zealand, it’s essential to do new zealand cautiously consults on digital cash guide aucklandnewsroom.com. For those interested in digital cash options, it’s wise to consult guides like the one available on AucklandNewsroom.com. These resources provide up-to-date advice on safely navigating online gaming and transactions. In terms of safety, modern casino machines are equipped with mechanisms that can halt play if an alarm is triggered and offer precise readings of clamping force to ensure secure operations.

As there are no moving parts or wear parts inside the plates, repairs are minimized, something very positive for any company and so that there are no unnecessary production stoppages. The sensors are able to monitor the systems at all times.

MAGBO solutions allow the assembly of any shape and size of mold, so it adapts to the different needs of industries, being very flexible for companies.

Quality is one of its main added values. There is an increase in rigidity and, as a consequence, the quality of components and parts is higher. Therefore, the useful life of the equipment increases and, at the same time, productivity and economic profitability.

A very important fact is that this machinery operates and functions without hydraulic oils, being the best solution to produce parts without environmental contamination.

These, among other properties, make MAGBO a reference, with years of experience and bringing the best to the plastic injection industries.

Technology and innovation for the plastics industries.

MAGBO offers greater competence to the industries, because customers have within reach high-tech equipment capable of generating higher quality parts, produced by an increase in rigidity and uniformity in the clamping.

In addition, MAGBO solutions contain a new CUW control, which is easy to install and combines the control panel with the electrical cabinet in a small box with quick connections.

It is also possible to have an actual reading of the clamping force. It provides the most accurate information on the performance and operability of the machinery and, in this way, it is possible to make the necessary adjustments.

In short, technology and innovation to make processes in the industries easier and to know the data at all times. This aspect is essential for the improvement and evolution of an industry. It is important to have companies and machinery specific to the sector, capable of providing the best solutions and innovations to the market and that are continuously updated.

Machinery for the plastic processing industry

Relying on the best plastic processing machinery such as MAGBO’s will make your industry more competitive, strong and stable.

Contact HAITIAN, a company dedicated to the import and sale of this type of equipment, and you will receive the best guidance in this regard, in addition to a fully personalized service tailored to your needs and requirements.

We are at your disposal to provide you with customized support on plastic injection molding machinery.

Ask us for information without obligation.