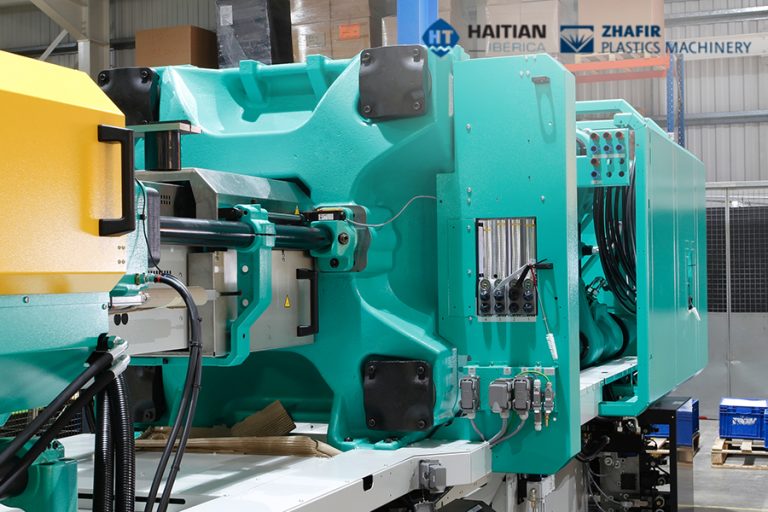

Injection molding equipment for plastics processing uses heat and pressure to inject molten material into a mold. This machinery is used in a wide variety of industries, from the production of small parts and components to large and very complete products.

What is plastic injection molding machinery used for?

Plastic converting machinery is a tool used to produce plastic objects and parts through the use of a mold and an injection process. This process consists of heating and melting the plastic, and then injecting it into a mold to create the desired shape. Thus, the use of injection molding equipment for plastic processing is one of the most common and efficient ways to produce plastic parts, components and objects on a large scale.

They are machines in the plastics industry that work by injecting molten plastic into a closed mold, where it cools and solidifies to create a part with the desired shape.

Injection molding machinery is a fast, precise and efficient process for producing a wide variety of products, including toys, electronics, automotive parts, consumer products and more. There are three main types of plastic injection molding machinery: hydraulic, hybrid and electric, each with its own advantages and disadvantages.

We’ll take a look at them below.

Hydraulic injection molding machines

Hydraulic injection molding machinery is equipment used in the plastics manufacturing industry to produce plastic objects through the injection molding process. This process involves heating and mixing plastic until it becomes a liquid, and then injecting it into a mold to shape it. Here are some important aspects about this type of equipment:

– Advantages of hydraulic injection molding machinery:

There are several advantages to choosing hydraulic injection molding machinery for plastics manufacturing. One of the most prominent is that it provides precise control over the injection speed, which allows for greater precision in the production of plastic objects. In addition, hydraulic injection molding machinery is capable of handling high-viscosity and high-pressure materials, making it ideal for the production of larger and heavier objects.

– Considerations to keep in mind when choosing hydraulic injection molding machinery:

There are a few things to keep in mind when choosing hydraulic injection molding machinery for your business. The first is to make sure you choose high-quality equipment from a reputable manufacturer, as this will ensure greater durability and reliable performance. In addition, it is important to consider the size and production capacity needed to meet the demands of your business. Finally, it is important to consider the budget available for the purchase of hydraulic injection molding machinery.

Hydraulic injection molding machinery is the oldest and most commonly used in the plastics industry. It uses a hydraulic system to control the speed and pressure of plastic injection. These machines are reliable and dependable, and are an excellent choice for applications that require precise control of speed and pressure. However, they are heavier and have a higher cost than electric and hybrid machines.

Hybrid and electric injection molding machinery.

Hybrid and electric injection machinery uses a combination of hydraulic and electric technology to control injection pressure and speed. This type of machinery is more energy efficient and is suitable for the production of smaller and lighter parts. In addition, hybrid and electric injection molding machinery is easier to maintain and is quieter than hydraulic machinery.

Hybrid injection molding machinery combines hydraulic and electric components to provide a more efficient and economical solution. These machines offer greater control over injection speed and pressure, as well as less energy and maintenance.

Electric injection molding machines use only electrical components to control the plastic injection molding process. They are lighter and more energy efficient than hydraulic machines, and have a lower cost. However, they can be less accurate than hydraulic or hybrid machines in applications that require precise speed and pressure control.

Therefore, choosing the right injection molding machine depends on several factors. As we said, one of the most important is to make sure you choose high-quality equipment from a professional company, such as HAITIAN. This guarantees durability and efficiency.

We are a company that imports and sells machinery for the plastic processing industry and we are at your disposal for whatever you need.

Contact us and ask for more information.