In the plastic injection industry, efficiency and speed are key factors to maintain competitiveness and reduce operational costs. One of the innovations that has revolutionized this industry is the quick mold and die change MAGBO machine. These machines allow companies to perform mold changes quickly and safely, minimizing downtime and maximizing production.

Quick mold and die change is an essential process in injection molding operations, as it allows manufacturers to quickly adapt to market needs and specific customer demands. With the growing need to produce high-quality plastic parts in smaller quantities and with shorter lead times, efficiency in mold changes has become more critical than ever.

Advantages of the MAGBO Machine

The MAGBO machine stands out in the market for its advanced features and its ability to deliver superior performance in quick mold and die changes. Below are some of the key advantages of the MAGBO machine:

Real-time Clamping Force Reading

One of the most important features of the MAGBO is its ability to accurately read the clamping force. This ensures that the mold is clamped with the correct force, which is crucial for the integrity of the molding process and the quality of the final product.

Removable Steel Cover

The MAGBO features a removable steel cover, which facilitates maintenance and cleaning access. This feature not only improves the durability of the equipment but also reduces downtime associated with maintenance tasks.

Temperature Monitor

The integrated temperature monitor in the MAGBO allows for precise control of thermal conditions during the molding process. Maintaining a constant and adequate temperature is essential for product quality and to avoid warping or defects in the molded parts.

Thin Thickness of 30mm

With a thin thickness of only 30mm, the MAGBO maximizes the usable space within the molding machine. This allows for greater flexibility in mold design and equipment configuration, which can translate into higher operational efficiency.

Slip Detection System

The slip detection system is another standout feature of the MAGBO. This system identifies any unwanted movement of the mold during the clamping process, helping to prevent mold damage and ensuring a secure and precise clamping.

Mold Recovery System

The MAGBO is also equipped with a mold recovery system that facilitates the removal and replacement of molds. This system significantly reduces the time required for mold changes, improving the overall efficiency of the production process.

Advanced Optional Technologies

In addition to its standard features, the MAGBO offers a variety of advanced optional technologies that can be customized to the specific needs of each customer. These options include automation systems, integration with quality control software, and other technological advances that can further enhance machine performance.

Rollers for Side Mold Loading

The rollers for side mold loading are an additional feature that facilitates the handling and installation of molds. These rollers allow molds to be loaded and unloaded laterally, saving time and reducing the physical effort required by operators.

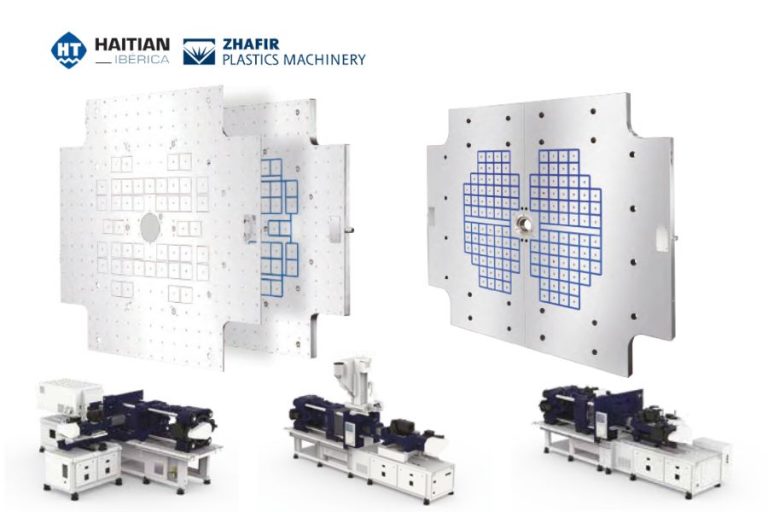

MAGBO Magnetic Clamping. Uniform and Distributed Clamping

The MAGBO’s magnetic clamping technology provides uniform and distributed clamping over the entire surface of the mold. Unlike traditional methods, which focus on a few parts of the mold perimeter, magnetic clamping ensures that the mold becomes practically part of the machine’s plates once magnetized.

This increase in rigidity and uniformity in clamping offers several significant benefits:

- Higher Quality Parts: Uniform clamping eliminates any displacement or misalignment of the mold, resulting in more precise and higher-quality parts.

- Increased Mold Repeatability: Mold stability during the molding process ensures that each produced part is consistent, which is crucial for maintaining high-quality standards.

- Reduced Maintenance: By minimizing mold wear and slippage, magnetic clamping technology significantly reduces mold maintenance requirements, leading to fewer interruptions and lower operational costs.

Main Features of Quick Mold and Die Change Machines

Quick mold and die change machines have become an indispensable tool in the plastic injection industry. Among the main features of these machines, the following stand out:

1. Speed and Efficiency

These machines are designed to minimize the time required to change molds and dies. This not only increases productivity but also allows for greater flexibility in production, which is crucial in a manufacturing environment where demands can change rapidly.

2. Safety and Precision

Quick mold change machines are equipped with advanced safety systems that ensure the mold is firmly clamped throughout the molding process. Additionally, the precision in mold placement and clamping reduces the risk of defects in the produced parts.

3. Integration with Automated Systems

The ability to integrate with automation and quality control systems allows companies to implement smart manufacturing solutions. This not only improves process efficiency but also ensures that products meet the highest quality standards.

4. Ease of Use

These machines are designed with ease of use in mind, with intuitive interfaces and easy-to-handle controls. This reduces the need for extensive operator training and allows mold changes to be performed quickly and efficiently.

5. Adaptability and Versatility

Quick mold change machines can adapt to a wide variety of molds and dies, making them extremely versatile. This adaptability allows companies to use a single machine for multiple applications, maximizing return on investment.

Haitian Ibérica, We are Distributors of MAGBO Equipment

At Haitian Ibérica, we are proud to be distributors of MAGBO equipment, leaders in quick mold and die change technology. Our mission is to provide innovative and high-quality solutions that enhance the efficiency and productivity of our customers in the plastic injection industry.

Are you interested in optimizing your production processes? Discover how the quick mold and die change machine MAGBO can transform your business. Contact us today for personalized advice and to learn more about our advanced solutions. At Haitian Ibérica, we are committed to your success and excellence in each of our products.