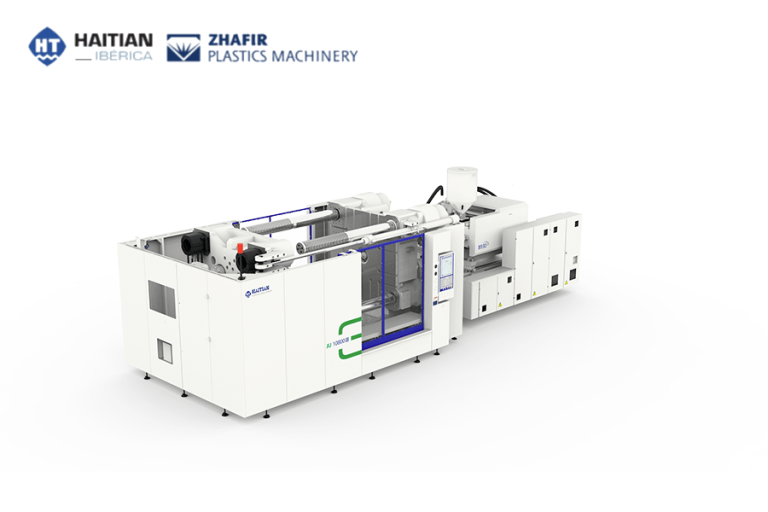

In the context of technological innovation and excellence in molding processes, Haitian’s JU III Series is presented as a decisive line of equipment for the transformation of plastics.

With years of experience and leadership in developing solutions in the sector, Haitian has raised the bar once again by introducing this new generation of molding machinery. Designed on the foundation of sustainable research and development, it represents a momentous advancement, seamlessly fusing advanced drive and control technology to deliver unparalleled performance.

Our company’s vision not only translates into incremental improvements, but a complete redefinition of the molding paradigm. With a design that incorporates advanced functions and user benefits, these equipment are positioned as a comprehensive solution for a wide variety of molding applications. From high-precision automobile parts to technological components with demands for surface quality, its flexibility is its distinguishing feature. In an industrial landscape where versatility and efficiency are essential, Haitian provides molding machinery that meets the requirements of the present and that anticipates and exceeds future demands.

This article will explore in detail the features, benefits and impact that these plastics converting equipment have on the industry, marking a significant milestone in operational efficiency, precision and sustainability.

Molding Machinery: Fundamentals and Applications

Molding machinery, in the industrial context, represents an essential category of equipment designed to shape plastic materials through the process of injection of molten plastic into specific molds.

These molds act as dies, defining the precise geometry of the final part being produced.

This is machinery that has become a vital component in the manufacturing of a wide range of products, from automotive components and packaging to toys and household appliances. Its main function lies in the ability to efficiently and consistently reproduce complex shapes and specific details, allowing the mass production of plastic items with high standards of quality and precision.

In essence, it operates by melting plastic granules that, once melted, are injected at high pressure into predefined cavities within a mold. Subsequently, the material cools and solidifies, adopting the exact shape of the mold.

This process not only ensures consistency in production, but also offers remarkable efficiency by shortening manufacturing cycle times.

Furthermore, the ability to adapt to different shapes, sizes and types of plastic positions it as an indispensable tool to meet the diverse demands of today’s market.

Haitian JU III Series Technological Innovation: Transforming Molding Machinery to a New Level

The JU III Series from Haitian, a supplier of equipment for transforming plastics, represents a paradigmatic evolution in molding machinery. This technological advance is manifested through substantial improvements over its predecessor, providing outstanding advantages for a wide variety of molding applications:

- Drive Technology: The JU III Series incorporates a servohydraulic system that redefines efficiency in the molding process. This drive technology allows a closing force ranging from 450 to 6600 tons, offering an injection capacity that varies between 792 and 80,170 cm³. This system guarantees fast cycles, precise movements and efficient clamping in short paths, significantly optimizing production times.

- Innovative Design and Control System: Equipped with the KEBA control system, Haitian’s JU III Series is positioned at the forefront of operational intelligence. The 15″ color touch screen and FFP V4 software provide precise digital control and an intuitive user interface. The innovative design, with a two-platen closing system and a distance between columns of 2400 x 2000 mm, gives the machine exceptional versatility by adapting to specific or general molding applications.

This unique combination of technologies allows Haitian’s JU III Series to stand out in the molding industry, offering users unmatched versatility when addressing various production challenges. The ability to adapt to different applications, from the manufacture of large parts such as garbage cans, to the production of high-precision automotive parts or technological components with surface quality requirements, consolidates it as the preferred solution, redefining the standards of the industry and taking molding to a new level of technological excellence.

Technological Advantages of the Haitian JU III Series

- Operational Advantages:

- Fast Cycle: It is distinguished by its ability to achieve fast cycles, thanks to a quick and smooth movement in the opening/closing of the mold, as well as fast clamping in short strokes. This efficient approach considerably shortens production cycle time, improving productivity and allowing greater responsiveness to market demands.

- Built-in Intelligence: Equipped with intelligent core hardware, it incorporates precise digital control compatible with the latest international information interface. The human-machine interface (HMI) is easy to use, providing operators with intuitive control over the molding process. This operational intelligence optimizes efficiency and ensures high-quality production.

- Reduced Footprint: The compact structure of the machine offers greater productivity per square meter. This feature not only maximizes usable plant space, but also contributes to overall operational efficiency by taking up less physical space.

- Technological Advantages:

- Large Injection Molding Capacity: Stands out for its extensive injection molding capacity, covering an extensive range of process coverage. This is achieved through a flexible combination of different injection units, allowing adaptability to a variety of materials and application requirements.

- Large Molding Area: With a wide opening and ejection path, it adapts to various application needs. This large molding area not only facilitates the production of large parts, such as trash cans and logistics boxes, but also ensures versatility in the manufacturing of high-precision components.

- Green Advantage: The high-efficiency and energy-saving power unit of the JU III Series proves to be highly dynamic and sensitive. With higher efficiency and lower energy consumption, Haitian prioritizes sustainability, offering users a significant green advantage in terms of energy efficiency and environmental responsibility.

Cutting-edge Technological Control: KEBA 2885 and More

Haitian’s JU III Series stands out in performance and also integrates cutting-edge technological control to enhance its operation:

- Advanced Touch Screen: The KEBA 2885 15″ color touch screen provides operators with an intuitive interface to monitor and control the molding process. Its advanced design makes it easy to configure and manage parameters, optimizing operational efficiency.

- FFP V4 Software and Atom Processor: FFP V4 software and 1.1 GHz to 1.6 GHz Atom processor ensure precise digital control and efficient execution of machine functions. With 512 MB DDR2 SDRAM memory, the JU Series III operates with agility and precision.

- Optional RFID Access Control and Extension Options: It is adaptable and extensible to incorporate additional features according to the user’s needs. In addition, it offers the option of user access control through RFID (contactless), improving security and customization in the operation of the machine.

Contact Haitian for the Cutting Edge in Plastics Processing Equipment

If you are looking for the cutting edge in plastic processing equipment, Haitian’s JU III Series is the answer to your molding needs.

Not only does it represent a significant leap in technology and efficiency, but it also offers exceptional versatility to adapt to various applications.

By contacting Haitian, you will have access not only to state-of-the-art machinery, but also to the experience and commitment of a leading company in the sustainable development of two-platen solutions.

Ask us for information without obligation.