Efficiency in changing molds is a fundamental pillar to guarantee continuous and competitive production. Every second counts in an environment where speed and precision are essential.

It is in this context, the collaboration between HAITIAN and MAGBO is key, since, as a company that imports and sells machinery for the plastic transformation industry, we only collaborate with the best brands in the sector.

That is why we offer innovation and cutting-edge solutions in molding equipment, such as those offered by MAGBO.

Its commitment to excellence and the constant search for the best technology have allowed it to stand out and have more efficiency and quality in its processes.

Throughout this article, we will explore in detail how your molding machinery is transforming the industry. From quick-change mold and die equipment to cutting-edge solutions that ensure more sustainable and efficient production, excellence and innovation are assured.

Molding Equipment: The Basis of Plastic Production

Molding equipment is the vital core of the plastic injection industry. These machines play an essential role in the creation of a wide range of plastic products, from automotive components to food packaging. In essence, they are the tools that shape the vision of designers and manufacturers, allowing the transformation of plastic resins into final products.

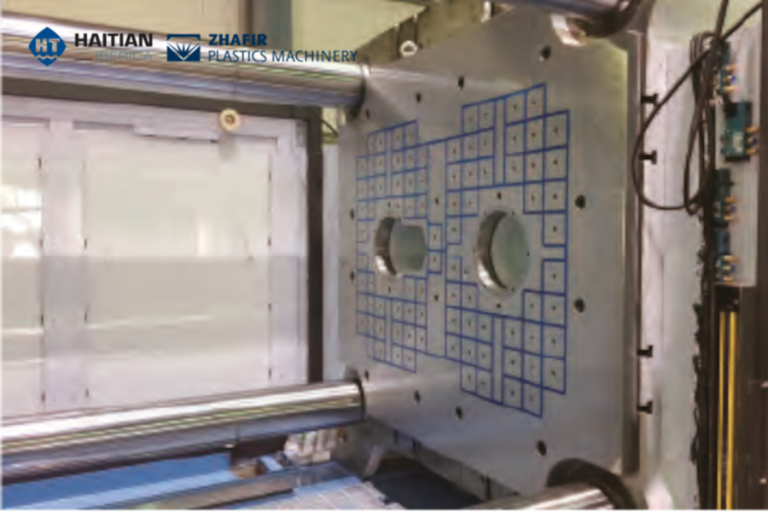

They comprise a series of complex components and a meticulous process that involves injecting molten plastic into molds, where it cools and solidifies to take the desired shape. However, what makes this equipment truly essential in plastic production is its ability to quickly change molds and its versatility to adapt to different production needs.

Efficiency and flexibility in changing molds are key in an environment where production cycles can be extremely tight and the ability to change products quickly is a determining factor for competitiveness. This is where MAGBO comes in, with its leading experience and technology in quick mold change solutions and innovative molding equipment.

MAGBO is a leader in the field of equipment for quick changing of molds and dies in the plastic injection industry. Its innovative magnetic solutions have proven to be a crucial element in improving productivity and profitability in the sector.

Removable All-Steel Cover: Flexibility and Durability

One of the most notable aspects of this equipment is its removable steel cover, with a thickness of 5 mm. This cover not only provides additional protection to the magnetic plates, but also allows for quick and easy maintenance. It offers the flexibility to make repairs if necessary, ensuring continued efficiency.

Versatility and Adaptability: MAGBO Equipment for Changing Demands

The characteristics of this machinery are ideal in the plastic industry:

- Perfect Adaptability: Meeting Changing Demands

MAGBO equipment is not only efficient, but also highly adaptable. They can meet the changing demands of the plastics industry, which is essential in a constantly evolving manufacturing environment.

- Ergonomics and Practicality: Facilitating Daily Work

Ergonomics is a fundamental consideration in the design of MAGBO equipment. They have been designed with operator comfort in mind, which not only increases efficiency but also staff satisfaction.

- Durability: A Long-Term Investment

Its durability ensures that it is not just a short-term solution, but a long-term investment in plastic production efficiency.

- Contributing to a Sustainable World: Clean Environment

MAGBO cares about the environment and has developed its solutions with a focus on sustainability, contributing to a cleaner and healthier world.

HAITIAN, together with MAGBO, is transforming the plastics industry with innovative and efficient solutions for rapid mold change.

Advantages of MAGBO Equipment

Likewise, the advantages of its implementation in the industry are many:

- Real Reading of the Clamping Force: MAGBO equipment offers an accurate and real-time reading of the clamping force, allowing detailed control and efficient management of the molding process.

- Removable Steel Cover: The removable steel cover provides additional protection to the magnetic platters, while allowing for quick and easy maintenance, contributing to operational efficiency.

- Temperature Monitor: The inclusion of a temperature monitor in MAGBO equipment guarantees precise control of molding conditions, which is essential to maintain product quality and avoid defects.

- Thin 30mm Thickness: Despite their thin 30mm thickness, MAGBO equipment maintains its robustness and performance, making it ideal for limited work spaces without compromising functionality.

- Slip Detection System: The incorporation of a slip detection system avoids common problems in the industry, improving the safety and precision of the molding process.

- Mold Recovery System: MAGBO equipment is equipped with a mold recovery system, which facilitates the management of molds and dies, allowing quick and efficient changes.

- Optional Advanced Technologies: Offers optional advanced technologies to meet specific production needs, ensuring equipment is versatile and adaptable to various applications.

- Rollers for Side Mold Loading: The rollers for side mold loading in MAGBO equipment facilitate the loading and unloading process, saving time and effort for operators.

These advantages make MAGBO equipment a solid choice for the plastic injection industry, providing efficiency, precision and versatility at every stage of the molding process.

Innovative Technology for Greater Competitive Advantage

MAGBO equipment stands out for its revolutionary approach to magnetic clamping, which brings significant advantages to the plastic injection industry.

This innovation results in increased rigidity and uniform clamping force distribution, which has a direct impact on the quality of the parts produced.

Innovative magnetic clamping technology therefore improves part quality and repeatability of the molding process and also reduces costs and time spent on mold maintenance. These advantages are essential to remain competitive in the plastic injection industry.

Frequently asked questions

-Are MAGBO equipment suitable for different types of plastic production?

Yes, MAGBO equipment is highly adaptable and versatile, making it suitable for a wide range of applications in the plastic injection industry. They can meet changing demands and adapt to various production needs.

-What is magnetic clamping in plastic molding industry?

Magnetic holding is a technology that uses magnets to hold molds and dies firmly in place on plastic molding machines. This technology is essential for fast and safe mold changing and ensures uniform clamping force distribution.

-Why is rapid mold change important in the plastic injection industry?

Rapid mold changeover is essential to adapt to changing market demands and maintain efficient production. It allows companies to adjust their production processes in an agile manner, which is essential for competitiveness in the plastic injection industry.

Ready to Transform Your Molding Process? Contact HAITIAN now

If you are interested in taking advantage of innovative MAGBO molding equipment solutions and experiencing the revolution in rapid mold change, do not hesitate to contact HAITIAN.

Our team is ready to provide you with detailed information about the products and services we offer in collaboration.

We will be happy to answer your questions, provide personalized advice and help you find the perfect solution for your plastic production needs.